Macroll Winding Machine

Macroll Winding Machine Specification

- Product Type

- Automatic Winding Machine

- General Use

- Winding Yarn onto Bobbins or Spools

- Material

- Mild Steel, Aluminum

- Type

- Macroll Winding Machine

- Weight (kg)

- Approx. 750

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Filling Selection

- Automatic

- Working Range

- 24 hours continuous operation

- Shedding

- Electronic Shedding

- Let Off

- Automatic

- Take Up

- Roller Type

- Beating

- Electromagnetic

- Filling Insertion

- Mechanical

- Yarn Package Stand

- 8 to 12 Spindles

- Temple

- Fitted Mechanical Temples

- Power

- 3.5 kW

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 2100 mm x 1300 mm x 1700 mm

- Color

- White & Blue

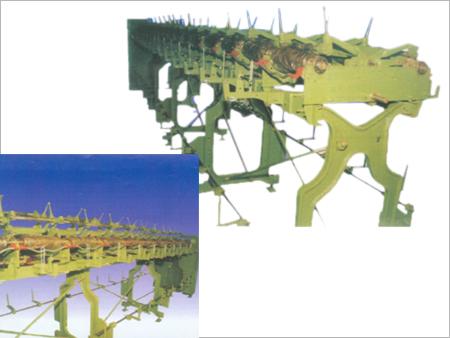

About Macroll Winding Machine

As one of the renowned manufacturers, exporters and suppliers in this domain, we are offering our clients the finest quality Macroll Winding Machine that is suitable for paper, film, foil & other flexible material. Offered machine is manufactured using world class raw material and cutting-edge techniques with high level of precision. This machine is used for winding diverse material in various industries. Moreover, we offer this Macroll Winding Machine in various specifications at highly competitive prices.

Features:

-

Sturdy construction

-

Durable finish standards

-

Easy to operate

-

Excellent durability

Unmatched Automation and Efficiency

The Macroll Winding Machine combines electronic dobby shedding, electromagnetic beating, and an advanced PLC control system for seamless, precise operation. The automatic functions including let off and filling insertion minimize manual intervention, maximizing productivity and reducing operational errors.

Robust Design Meets Versatile Functionality

Constructed from high-grade mild steel and aluminum, this machine is engineered for durability and reliability in industrial environments. It supports 8 to 12 spindles, making it adaptable for various production requirements, and is capable of uninterrupted 24-hour operation.

Consistent Quality for Yarn Producers

The combination of automatic filling selection, mechanical temples, and controlled winding tension ensures uniform yarn winding. With computerized control and automatic processes, the end product meets stringent quality standards, essential for suppliers and exporters.

FAQs of Macroll Winding Machine:

Q: How does the electronic dobby shedding system enhance the Macroll Winding Machines performance?

A: The electronic dobby shedding system provides precise control over yarn movement, resulting in accurate and consistent shedding. This technology reduces mechanical wear, allows quick pattern changes, and improves the overall efficiency and reliability of the winding process.Q: What are the benefits of using an automatic let off mechanism in this winding machine?

A: The automatic let off mechanism maintains constant yarn tension during winding, which ensures uniform package formation and minimizes thread breakage. This leads to higher production quality and reduced manual adjustments, saving time and labor costs.Q: When can the Macroll Winding Machine operate continuously, and how does this impact productivity?

A: This machine is designed for 24-hour continuous operation, allowing manufacturers to maximize throughput without frequent stoppages. Its robust build and automated systems ensure minimal downtime, significantly improving overall productivity in yarn processing facilities.Q: Where can this Macroll Winding Machine be utilized most effectively?

A: The Macroll Winding Machine is ideal for textile mills, yarn spinning units, and manufacturing facilities in India seeking automated, high-capacity winding solutions. Its adaptability makes it suitable for exporters, suppliers, and traders involved with large-scale yarn production.Q: What is the process for winding yarn with this Macroll machine?

A: The process involves feeding yarn onto the machine, which then automatically manages let off, shedding, and filling insertion using its computerized PLC control. Yarn is wound onto bobbins or spools via the roller-type take up, all while maintaining optimal tension and alignment.Q: How does the PLC control system contribute to the machines operation?

A: The PLC control system automates monitoring and adjustment of various machine functions. It enhances precision, streamlines workflows, and allows easy troubleshooting, resulting in efficient operation and consistent output quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS