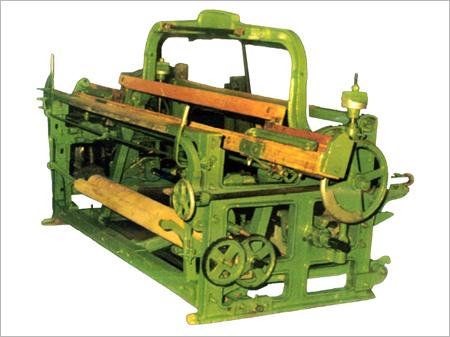

Jute Loom Machine

Price 120000 INR/ Piece

Jute Loom Machine Specification

- Product Type

- Jute Loom Machine

- General Use

- Jute Fabric Weaving

- Material

- Other

- Weight (kg)

- Approx. 1500 Kg Tonne

- Computerized

- No

- Filling Selection

- Manual/Mechanical

- Working Range

- Multiple Fabric Widths

- Shedding

- Cam Shedding Mechanism

- Let Off

- Automatic Let Off

- Take Up

- Automatic Take Up

- Beating

- Manual or Mechanical Beating

- Filling Insertion

- Manual/Automatic

- Yarn Package Stand

- Included

- Temple

- Roller Temple

- Water Suction

- No

- Dimension (L*W*H)

- Approx. 3500 x 2000 x 1700 mm Foot (ft)

- Color

- Green Coating Finish

Jute Loom Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Jute Loom Machine

We have marked a distinct position in the market by providing excellent quality Jute Loom Machine that is suitable for producing plain and twill cloth. Offered machine is manufactured using supreme class raw material and latest technology in compliance with set industry norms. This machine is also checked on several quality parameters to ensure its trouble free functioning. Further, this Jute Loom Machine is available in various specifications as per the need of the clients.

Features:

- Longer service life

- High durability

- Easy installation

- Excellent performance

Specification

|

Machine Speed |

50-150 rpm |

|

Usage/Application |

Weaving Process for Jute |

|

Brand |

Pawan |

|

Product Code |

P-02 |

|

Power |

5 Horsepower |

|

Power Source |

Electric |

Robust Construction Designed for Industrial Use

Engineered from high-grade cast iron and steel, this jute loom promises long-lasting durability even under continuous operation. Its substantial build supports consistent fabric weaving with minimal maintenance, making it perfect for high-volume textile manufacturing environments.

Versatile Shedding and Filling Options Enhance Productivity

Equipped with an electronic dobby and cam shedding mechanism, the loom adapts to varied pattern weaving needs. Both manual and automatic modes are available for filling insertion and beating, offering flexible operation according to fabric requirements and skilled workforce availability.

Simple Operation and Wide Compatibility

Mechanical control wheels provide straightforward management without complex electronics. The included yarn package stand and roller temple ensure stability and fabric quality. Designed for use across multiple fabric widths, this loom is a practical fit for different jute textile applications.

FAQs of Jute Loom Machine:

Q: How does the automatic take up and let off mechanism benefit jute weaving?

A: The automatic take up and let off mechanisms streamline the weaving process by maintaining consistent fabric tension and smooth cloth winding. This reduces manual adjustments, leading to higher quality jute fabric and increased overall productivity.Q: What types of jute fabrics can be woven on this loom?

A: This loom supports weaving a variety of jute fabrics, thanks to its adaptable working range and shedding mechanisms. It is suitable for producing different widths and patterns required in jute bags, carpets, and upholstery.Q: When is manual filling insertion preferred over automatic?

A: Manual filling insertion is beneficial when handling intricate designs or specialty yarns that require careful attention. It allows operators greater control over the weaving process for unique or small-batch production.Q: Where should this loom be installed for optimal performance?

A: For best results, install the loom in a stable, well-ventilated industrial space with sufficient floor area to accommodate its dimensions (approx. 3500 x 2000 x 1700 mm) and facilitate smooth workflow around the machine.Q: What is the process for shedding with the electronic dobby and cam mechanisms?

A: The electronic dobby enables rapid pattern changes electronically, while the cam mechanism offers mechanical shedding for simpler designs. Together, they enhance the looms ability to handle diverse weaves efficiently.Q: How is the mechanical control wheel system operated?

A: Operators use the mechanical control wheels to adjust loom settings and manage operations. This intuitive interface removes the necessity for computerized programming, thus simplifying training and maintenance.Q: What are the key benefits of choosing this loom for jute fabric weaving?

A: Key advantages include robust construction, versatile design supporting various weaving operations, reduced manual intervention, and compatibility with multiple fabric widths. These features collectively ensure reliable, high-volume output and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Jute Mill Machinery Category

Jute Loom Machines

Material : Other, Mild Steel

Control System : Other, PLC

Automatic : Yes

Computerized : No

Take Up : Other, Positive

Type : SemiAutomatic/Automatic

Roller Softener Machine

Material : Other, Mild Steel / Stainless Steel

Control System : Other, Manual / PLC Based (Optional)

Automatic : Other, SemiAutomatic / Optional Fully Automatic

Computerized : No

Take Up : Other, Manual/Automatic (Optional)

Type : Softening / Finishing Machine

Bag Printing machine

Material : Steel Alloy

Control System : Frequency Speed Control

Automatic : No

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS