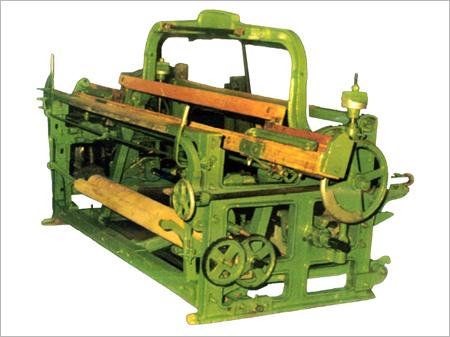

Jute Loom Machines

Jute Loom Machines Specification

- Product Type

- Jute Loom Machine

- General Use

- Jute Fabric Manufacturing

- Material

- Mild Steel

- Type

- Semi-Automatic/Automatic

- Capacity

- 500-1000 m/day

- Weight (kg)

- 980

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC

- Reed Width

- 145 cm

- Filling Selection

- Single/Multiple

- Weft Density Range

- 6-18 picks/cm

- Working Range

- 120-145 cm

- Spinning Method

- Projectile

- Shedding

- Cam or Dobby

- Let Off

- Manual or Automatic

- Take Up

- Positive

- Beating

- Crank Beat-up

- Filling Insertion

- Manual/Automatic

- Yarn Package Stand

- Available

- Temple

- Rotary

- Water Suction

- No

- Power

- 3.5 kW

- Voltage

- 220V/415V

- Dimension (L*W*H)

- 4300*2450*1850 mm

- Feature

- High Durability, Robust Construction, Easy Maintenance

- Color

- Green

About Jute Loom Machines

Take advantage of the elite performance offered by our Heavy Duty Jute Loom Machines. Specifically designed with a robust frame structure, these machines deliver high-efficiency output with low noise operation and automatic centralized lubrication. Ideal for sack, hessian, and sacking cloth production, they feature Preeminent stability, variable speed via a frequency drive, and laureate-level safety standards including emergency stops and safety guards. With quick access to spare parts and easy maintenance, you can explore seamless jute fabric manufacturing. Benefit from durable mild steel construction, positive take-up, automatic let-off options, and customized filling insertion, ensuring a superior, reliable, and versatile production experience.

Versatile Uses and Features of Jute Loom Machines

Jute Loom Machines are engineered for general and specific applications in jute fabric manufacturing, including the production of sacks, hessian, and sacking cloth. These preeminent machines are known for robust construction, high durability, and stable, smooth operation. Other features include an automatic lubrication system, variable frequency speed adjustment, and the convenience of both manual and automatic operation. Users also benefit from easy maintenance, availability of spare parts, and a wide working range, making these machines ideal for heavy-duty industrial environments.

Order Processing, Sample Supply, and Payment Flexibility

Order processing for Jute Loom Machines is streamlined to ensure quick response and reliable supply to customers. Samples are available upon request for clients looking to explore product performance before committing to bulk orders. The main domestic market is India, with extensive support for exporters, manufacturers, suppliers, and traders. Payment terms are flexible to accommodate client needs, with asking prices provided transparently. Customers benefit from assured sample availability, efficient dispatch, and dependable supply chains.

Versatile Uses and Features of Jute Loom Machines

Jute Loom Machines are engineered for general and specific applications in jute fabric manufacturing, including the production of sacks, hessian, and sacking cloth. These preeminent machines are known for robust construction, high durability, and stable, smooth operation. Other features include an automatic lubrication system, variable frequency speed adjustment, and the convenience of both manual and automatic operation. Users also benefit from easy maintenance, availability of spare parts, and a wide working range, making these machines ideal for heavy-duty industrial environments.

Order Processing, Sample Supply, and Payment Flexibility

Order processing for Jute Loom Machines is streamlined to ensure quick response and reliable supply to customers. Samples are available upon request for clients looking to explore product performance before committing to bulk orders. The main domestic market is India, with extensive support for exporters, manufacturers, suppliers, and traders. Payment terms are flexible to accommodate client needs, with asking prices provided transparently. Customers benefit from assured sample availability, efficient dispatch, and dependable supply chains.

FAQs of Jute Loom Machines:

Q: How does the automatic centralized lubrication system benefit the Jute Loom Machines operation?

A: The automatic centralized lubrication system ensures consistent oil distribution to critical machine parts, reducing wear, minimizing downtime, and enhancing overall operational reliability.Q: What specific applications are these Jute Loom Machines suitable for?

A: These machines are primarily used for manufacturing jute fabric products such as sacks, hessian, and sacking cloth, catering to diverse industrial requirements.Q: Where can the Jute Loom Machines be supplied, and who are the main market participants?

A: Jute Loom Machines are mainly supplied across India and are supported by exporters, manufacturers, suppliers, and traders, making them widely accessible within the domestic market.Q: What process does the machine follow for high-efficiency jute production?

A: The machine employs positive take-up, efficient projectile spinning, electronic dobby for shedding, and optional manual or automatic filling insertion, all controlled via a PLC system to maximize output and stability.Q: When are spare parts available for maintenance?

A: Spare parts are readily available to ensure uninterrupted operation and easy maintenance, supporting ongoing machine efficiency and reducing potential downtimes.Q: How does the variable frequency drive contribute to the machines performance?

A: The variable frequency drive offers precise speed control, allowing operators to adjust the machines running speed for optimized performance, energy efficiency, and adaptability to various production requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Jute Mill Machinery Category

Jute Loom Machine

Material : Other, Heavy Duty Cast Iron and Steel

Control System : Other, Mechanical Control Wheels

Computerized : No

Beating : Other, Manual or Mechanical Beating

Take Up : Other, Automatic Take Up

Dimension (L*W*H) : Approx. 3500 x 2000 x 1700 mm

Roller Softener Machine

Material : Other, Mild Steel / Stainless Steel

Control System : Other, Manual / PLC Based (Optional)

Computerized : No

Beating : Other, Manual

Take Up : Other, Manual/Automatic (Optional)

Dimension (L*W*H) : Approx. 3500 x 1800 x 1800 mm

Bag Printing machine

Material : Steel Alloy

Control System : Frequency Speed Control

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS